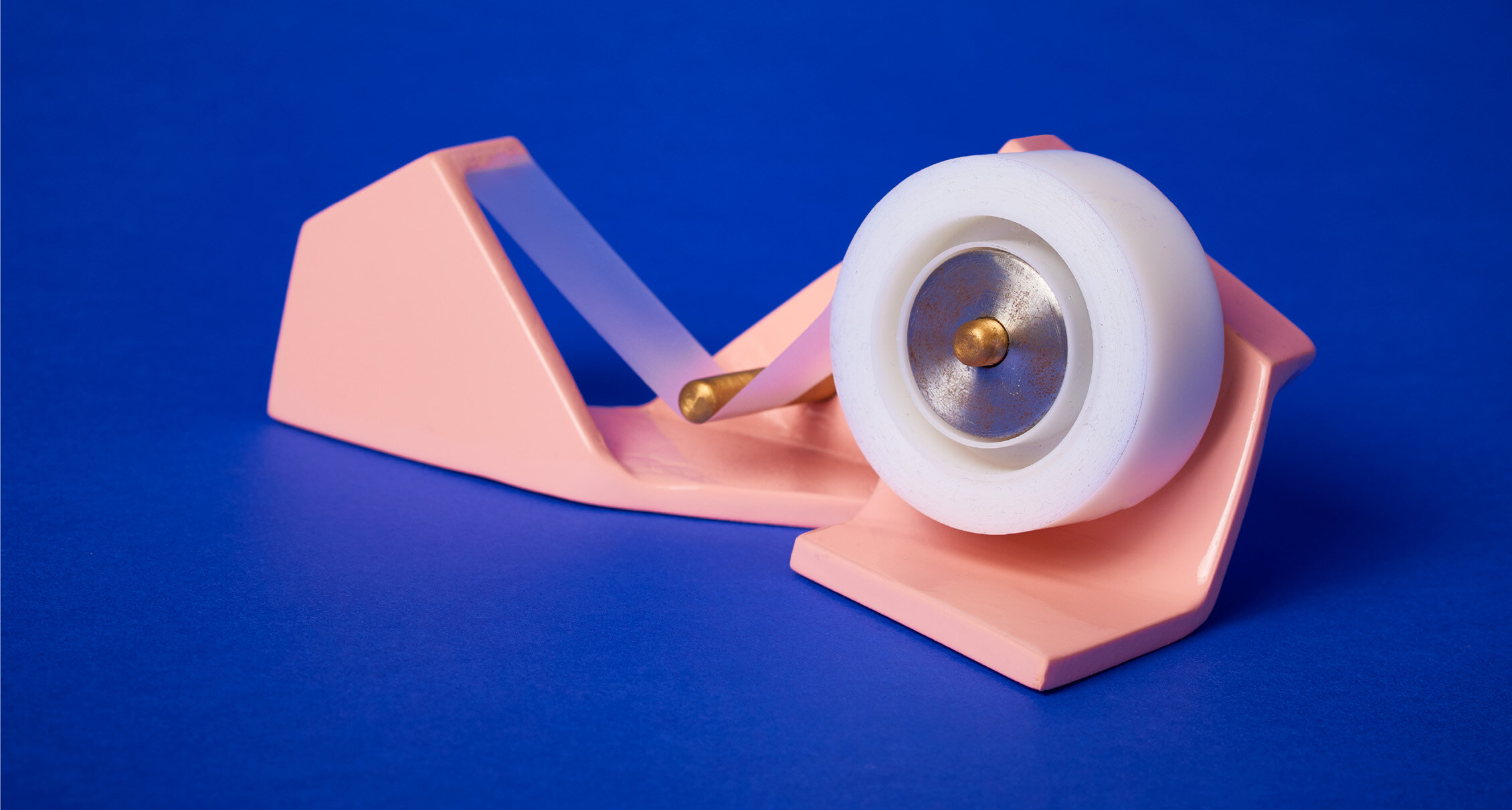

Inspired by the random and haphazard shape of a bent piece of scrap metal.

Process

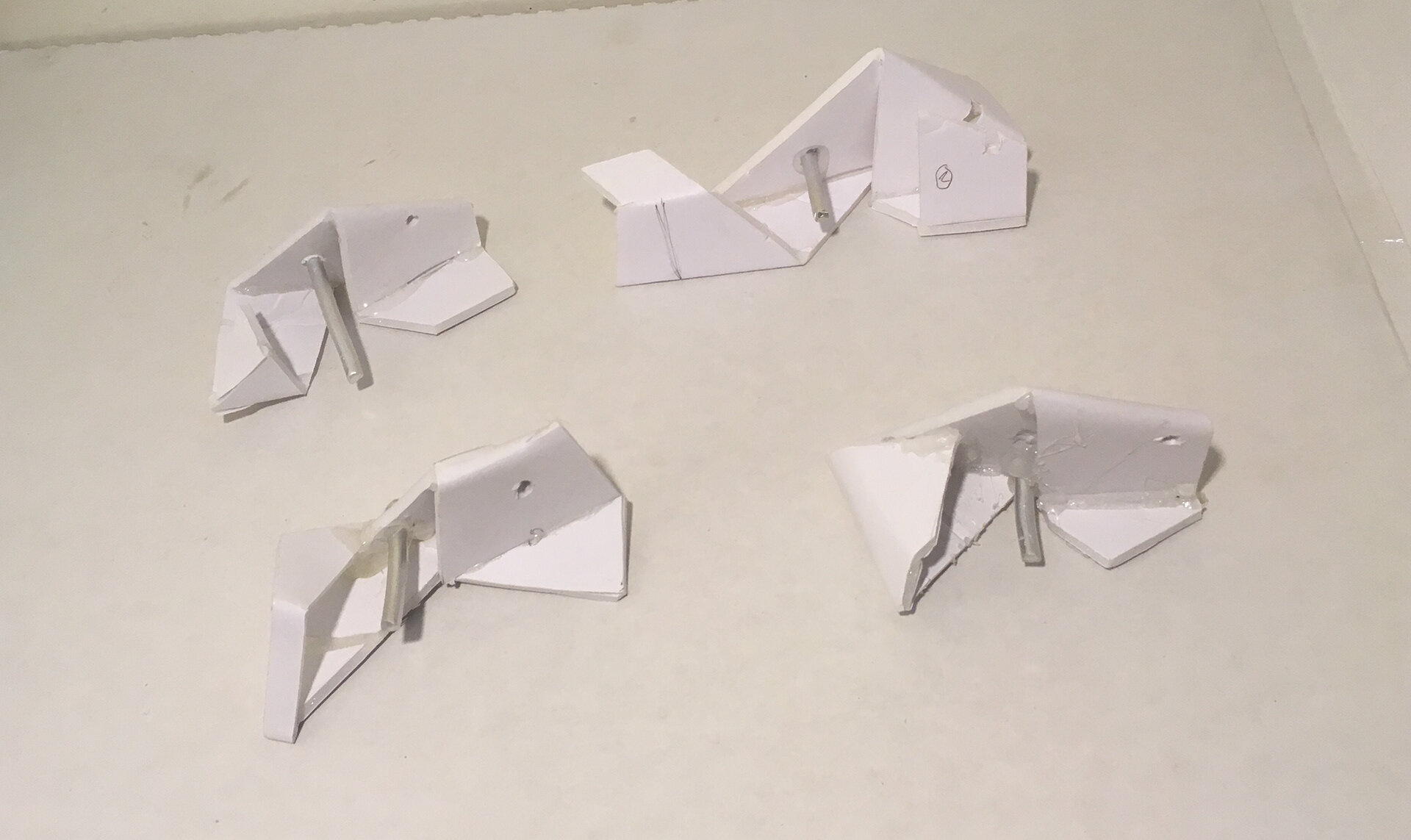

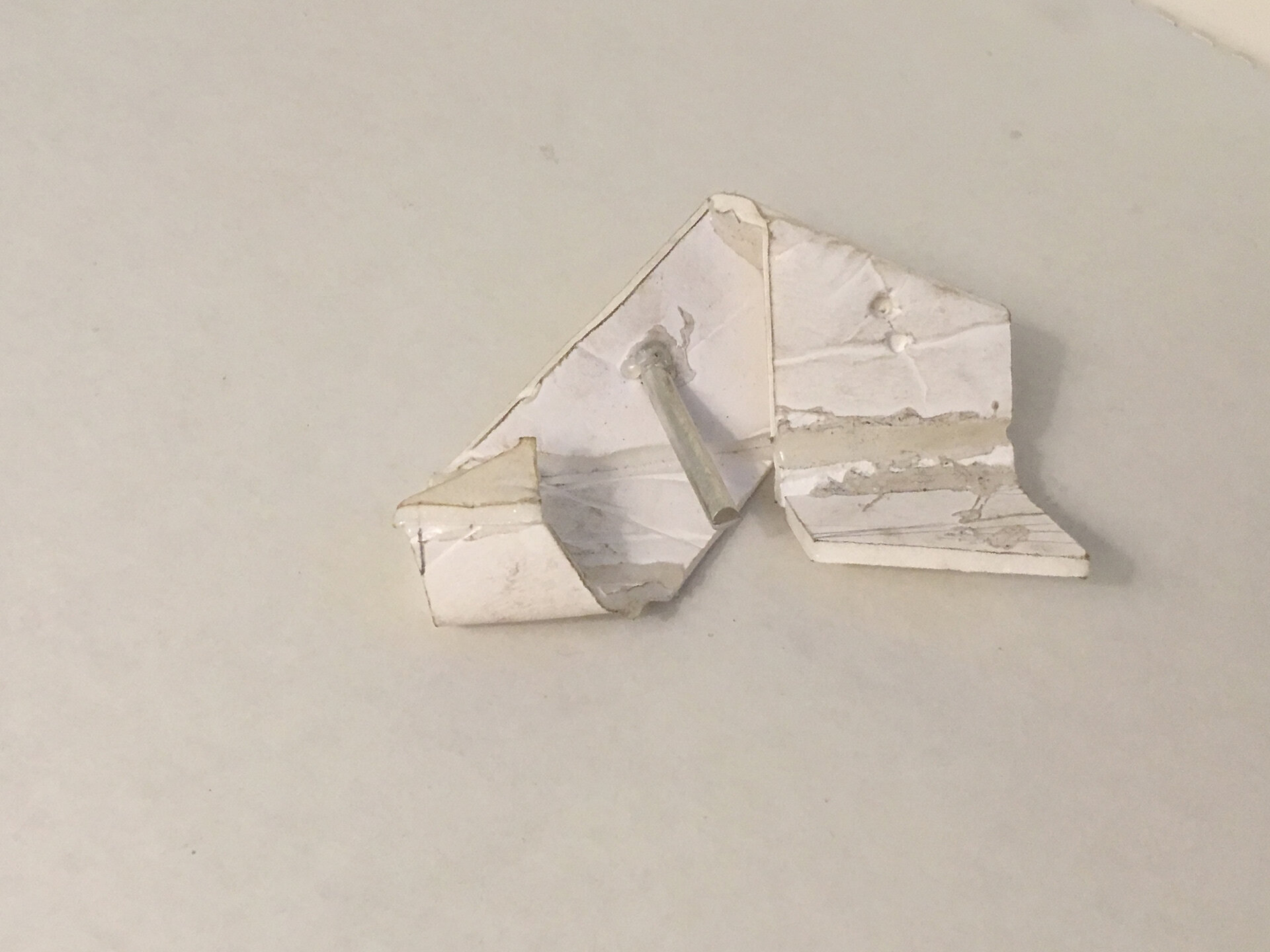

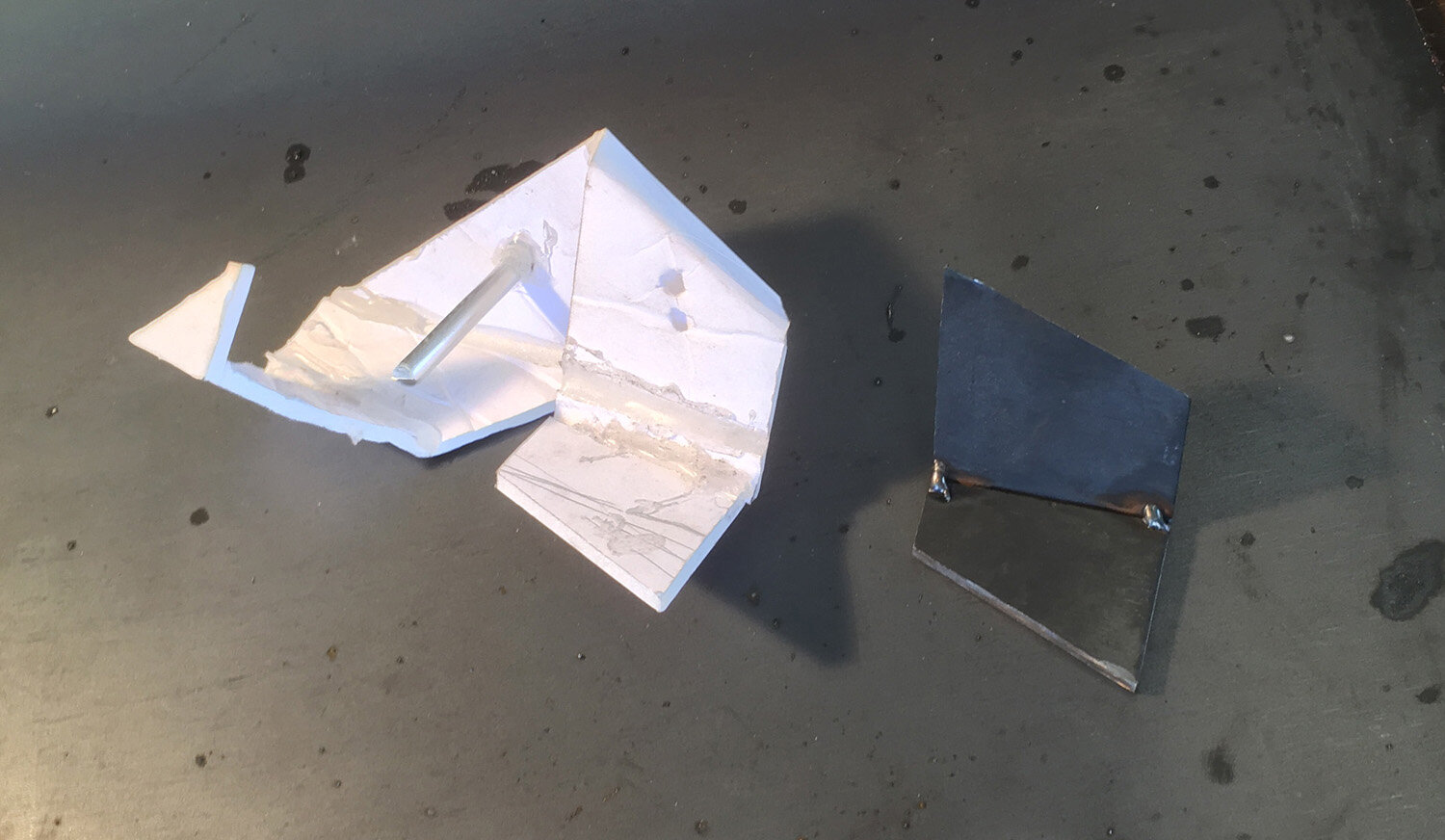

To create the Happy Accident Tape Dispenser, I experimented with form by gluing pieces of foam core together.

This was a very loose, free-flowing process—almost like a three-dimensional sketching exercise.

Eventually I came up with a prototype that not only fit my concept, but was also aesthetically pleasing and fully functional.

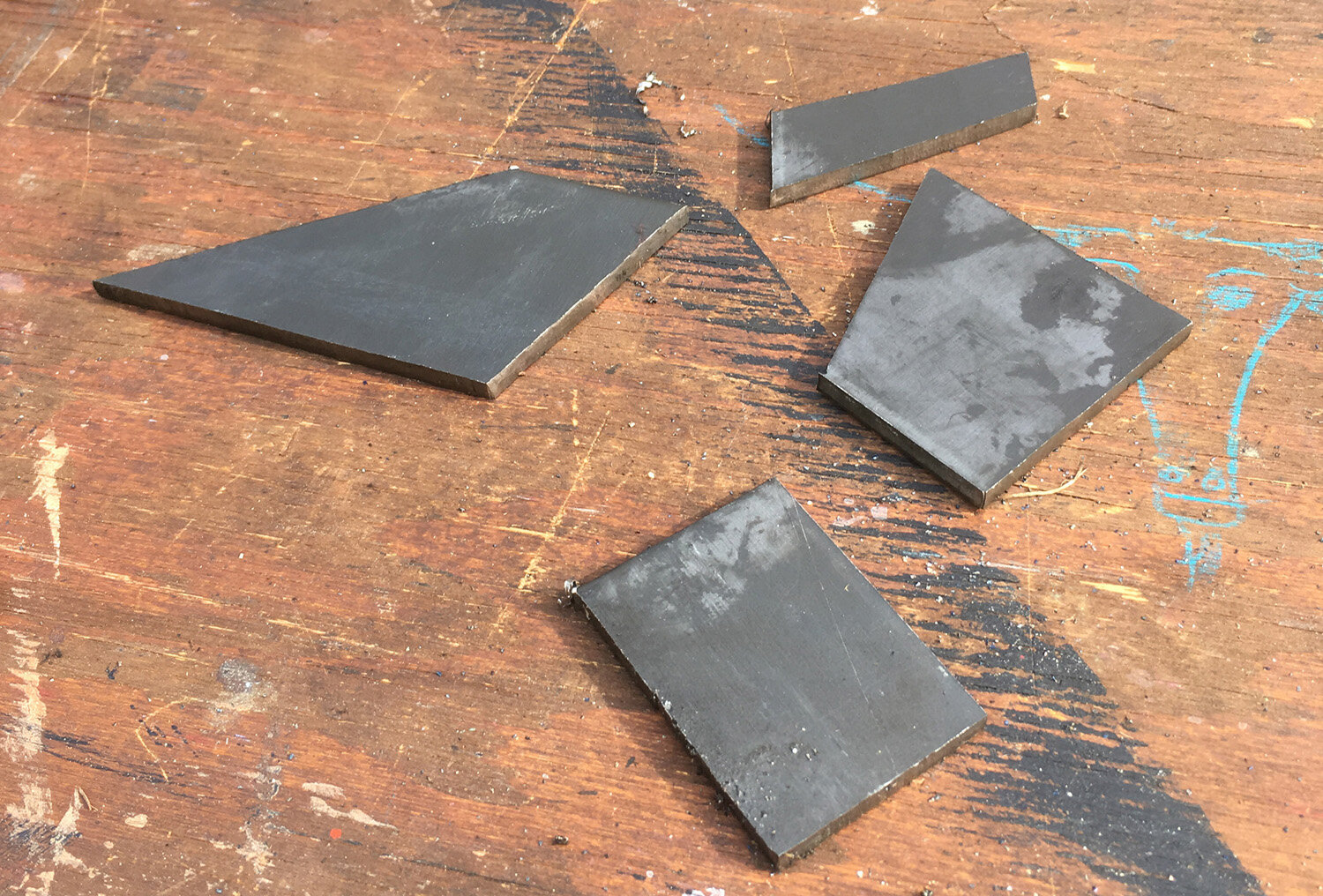

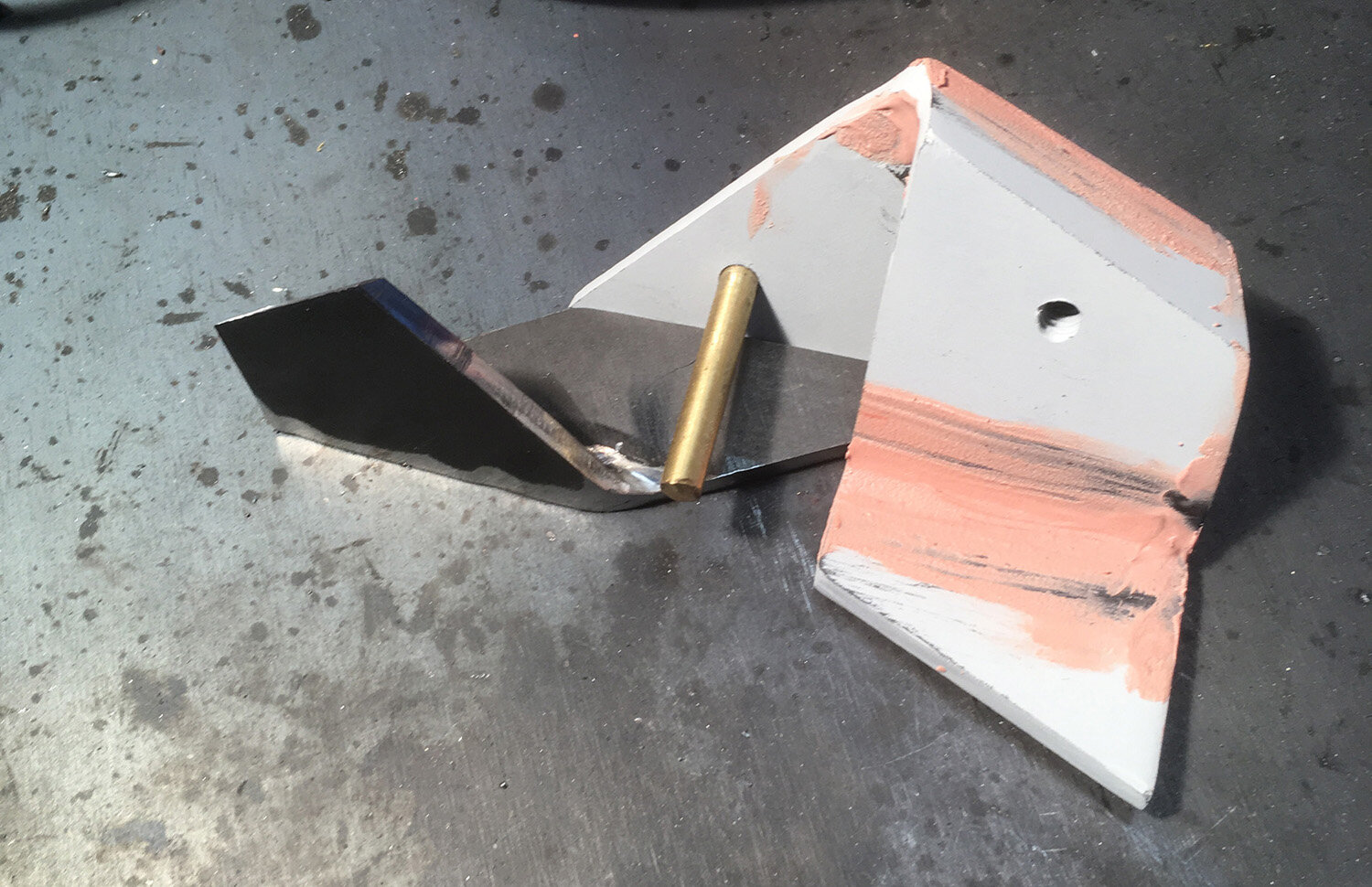

The next step was to recreate the foam core piece in metal.

Working with 1/4" plate steel, I knew that I could not simply bend a piece of stock into the form I had designed.

What I could do, however, was cut out flat sections of the form and weld them back together to form each “bend.”

This would achieve the illusion of a continuous bent form, while working within the confines of my heavy duty material.

After hours of welding, cutting, chamfering, and re-welding, the form finally came to life in steel.

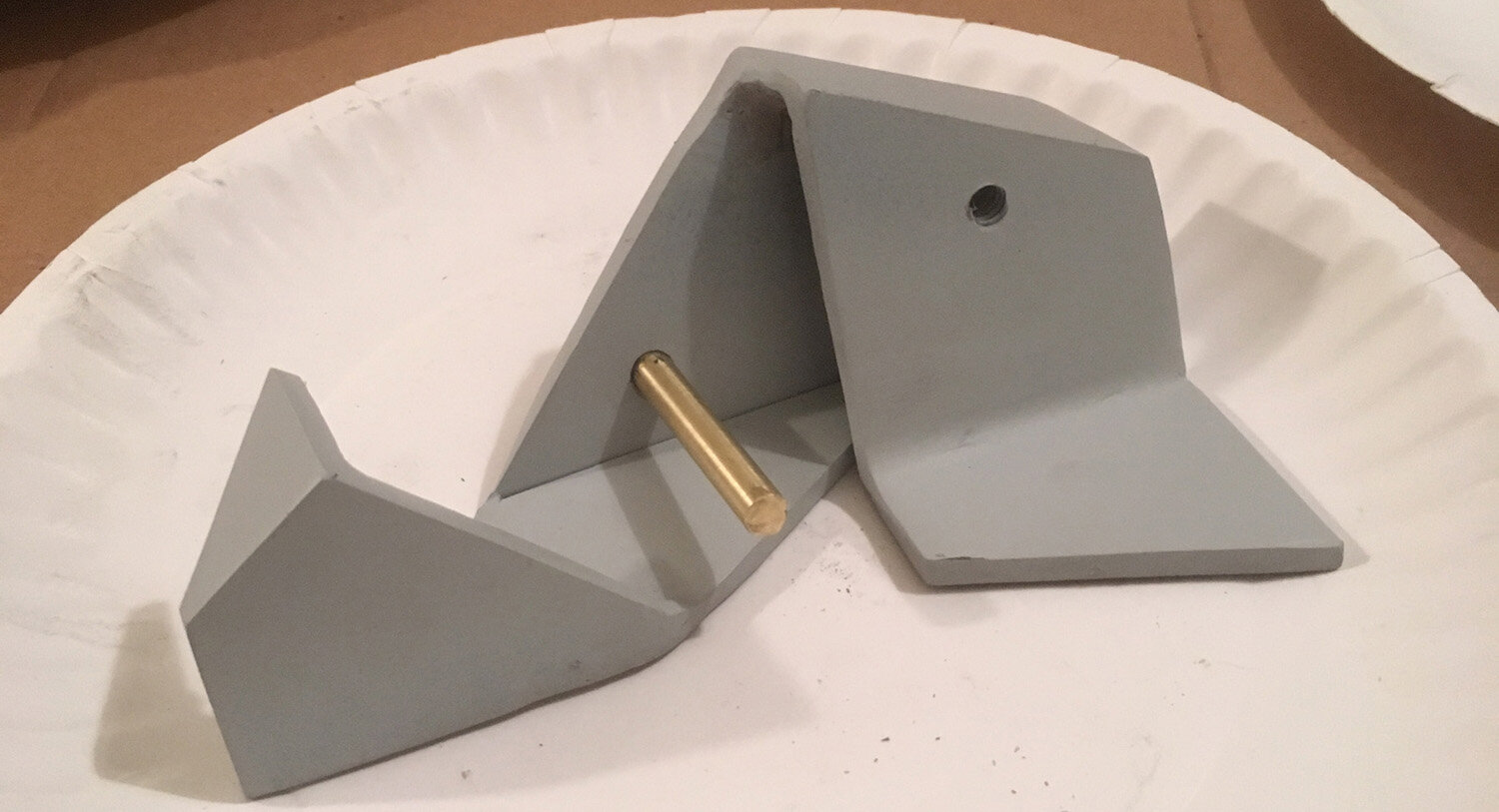

Once the form was complete, finishing was a process of filling the cracks with Bondo, then sanding, priming, and painting.

Thank You for Viewing this project

View More